How Many Vessels Are Registered In Manteca, Ca

The times of striking bacon differences between jobs at sea on merchant vessels and offshore fleet are long gone. However, a career in offshore remains quite highly-seasoned as wages are still decent and the duration of contracts rarely goes beyond iv months. This is a powerful incentive, indeed; so many seafarers strive to make a move to the oil and gas manufacture.

Therefore, we've decided to explore offshore fleet jobs and scrutinize every blazon of offshore vessel from the well-nigh popular to the exotic ones.If you are interested in the money side, delight read our Salary Gap Betwixt Nationalities article.

Accommodation Barge and Accommodation Ship

Ballast Handling Tug Supply Vessel (AHTS)

Cablevision Laying Vessel

Crew Boat

Diving Support Vessel (DSV)

Drilling Platform

FPSO (Floating Production Storage and Offloading)

Jack Upward Rig

Multi Role Support or Supply Vessels (MRSV)

Offshore Construction Vessel (OCV)

Pipe Laying Vessel

Platform Supply Vessel (PSV)

ROV Support Vessels

Seismic Vessels or Survey Ships

Shuttle Tanker

Wind Farm Installation Vessels (WIV)

Accommodation Barge and Adaptation Ship

Adaptation Barges are inalienable parts of the offshore industry. These are shallow draft vessels which are moored next to the offshore sites to provide additional accommodation facilities whenever a rig or platform is incapable of fitting all the offshore personnel.

Today these barges are usually equipped with cranes and maintenance equipment so as to perform some offshore construction work also. Merely it'due south not all work and no play; modernistic AWBs might be fitted with a bar, movie house, gym, conference rooms and anteroom for meetings likewise every bit a swimming puddle.

Accommodation Clomp Jobs

Anchor Handling Tug Supply Vessel (AHTS)

Anchor Handling Tug Supply Vessel (AHTS) is another ship that tin can be found at any drilling site. AHTS vessel is truly universal as it combines a number of functions: tows rigs and platforms; anchors and moors mobile structures into the position at the site and supplies them afterwards.Big ships are capable of working in deep waters, for instance in Brazil or the Arctic region.

AHTS ships are defined by the required bollard pull, so they have a very distinct blueprint with a big propeller, hull shape that provides the maximum immersion and stability as well as a range of specific deck equipment such as winch, stern roller, etc. Even so, their virtually distinctive features are powerful engines with BHP reaching 12240 and more than (to compare 25 000 DWT Bulk Carrier will be fitted with a far less powerful main engine of approx. 6946 BHP).

At that place are usually upward to 20 seafarers onboard AHTS vessels. Meanwhile, the coiffure of AHT ships might be smaller. Anchor Treatment Tugs (AHT) are very similar to AHTS and perform the aforementioned role, but tend to be smaller and less technologically advanced.

AHTS Jobs

AHT Jobs

Cable Laying Vessel

Offshore industry doesn't circumduct effectually oil and gas alone; and Cable Laying Vessels are the all-time proof of this statement. They are designed for the specific purpose of laying underwater cablevision networks.

Imagine the level of our dependence on this kind of communication that it proves to be economically sound to build huge vessels devoted to the sole purpose of cables' installation.

To ensure the maximum efficiency Cable Layers usually can lay the main and auxiliary umbilicals simultaneously. In add-on, they are equipped with a profound DP system and both hydraulic and pneumatic cablevision laying systems.

Cable Laying Vessel Jobs

Crew Boat

Crew Boats are the offshore vessels that are used for transportation of personnel and consumables (water, fuel) when the offshore site is situated inside the 200 nautical miles (370 km) distance.

These vessels can differ in size from 30-to-lx ft (9.one to 18.iii m) to large 200 ft (61m) ships that can send up to 100 marine specialists. Commonly, crew boats are fast (option up a speed of approx. 33 knots) and have a coiffure of 4 – five seafarers.

The largest crew gunkhole in the world today is catamaran Muslim Magomaev built in 2015. It boasts an overall length of seventy thousand and travels at a maximum speed of 38 knots.

Crew Boat Jobs

Diving Support Vessel (DSV)

Today DSVs tend to exist 1 of the nearly sophisticated offshore vessels. Their part is to provide a base for diving specialists who carry underwater maintenance or inspections of mobile platforms, rigs, pipelines and their connections, well-heads, etc.

Therefore, DSV is usually fitted with a moonpool (open surface area in the center of the vessel where divers' and ROV's operations get-go their operation) and recompression chamber. In improver, Diving Support Vessels e'er are provided with a DP3 course positioning system due to safety requirements.

Scandi Arctic is reputedly the almost technologically advanced DSV these days. She is a saturation dive support vessel equipped with the 24-man diving complex with Hyperbaric Monitoring and Control System.

Saturation diving is used for the most challenging and hard-to-accomplish offshore jobs requiring to create the pressurised environment filled with oxygen-helium mixture where defined alive for the unabridged contract.

Diving support requires navigational perfection, so Scandi Arctic is DP3 form vessel; and is fitted with avant-garde National oilwell crane 400t-15m with wire capacity 2000 m to be able to perform some Inspection, Repair and Maintenance (IRM) operations.

DSV (Diving Support) Jobs

Drilling Platform

People drill for oil from the submerged wells from the end of the 19th century. The first such production started in the Grand Lake St. Marys in Ohio in 1891, but the offshore drilling in the course nosotros know (deep wells, semi-submersibles and self-sufficient drilling platforms started only in the mid-20th century).

Jack upward rigs emerged in 1954 with the demand to drill on the depth more than than 30 meters (98ft); while semi-submersible platform was invented by accident in 1961.

Beat had a submersible 4-cavalcade drilling rig called Blue Water Rig No.1 in the Gulf of United mexican states, but its structure was scarce and the pontoons failed to back up the weight of the rig sufficiently. Therefore, the rig was towed at a draught midway between the deck and the pontoons. It was noticed that the motions of this draught is very small and it's more reasonable to operate the rig in this floating mode.

Since that time half dozen generations of semi-submersibles have been developed each generation able to drill in deeper waters. At nowadays the 6th generation operates in waters deeper than 3000 m.

Semi-submersibles use Dynamic Positioning to stay above the well; and anchors in shallower waters; they unremarkably are connected to the ocean flooring by umbilicals as stock-still structures are not applied in such depths. Whereas stock-still drilling platforms operate in less deep waters and are stock-still to the shelf.

The largest oil rig in the world is Berkut. Information technology was congenital to develop the plentiful Arkutun-Dagi oilfield in Okhotsk Ocean. The giant weighs unimaginable 200 000 t and is constructed on a gravity-based construction (GBS) fixed to the seabed at a depth of 35 metres. Information technology is estimated that 52,000m³ of concrete and 27,000 tons of steel reinforcing bars were used to build the legs. Every bit a effect, Berkut can withstand the ice pressure, eighteen grand waves and even a magnitude 9 earthquake. Read more than in our Offshore Giants article.

Drilling Platform Jobs

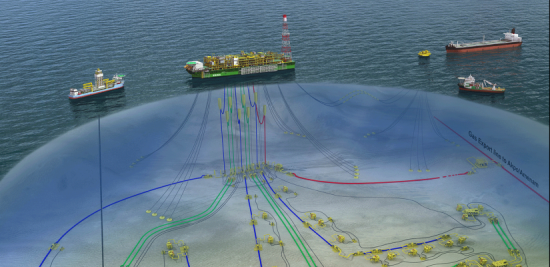

FPSO (Floating Production Storage and Offloading)

An FPSO is a floating unit used in the oil and gas industry for production and storage of hydrocarbons. FPSO are normally called for the oil abundant areas located away from the developed pipeline infrastructure.

FPSO job is to produce, process and store oil itself; alternatively, she collects it from the subsea template or nearby rig. The risers that come from the seabed are connected to the special mechanism (turret). The vessel is able to rotate around information technology to ensure prophylactic or even disconnect temporarily from the subsea infrastructure and sail abroad to escape severe weather.

The first FPSO to obtain such a unique adequacy was Crush's Turritella . She is stationed in the Stones oilfield in the Gulf of United mexican states and is the deepest FPSO in the earth operating in a water depth of 2,900 meters (9,500 feet) making her the world's deepest Oil & Gas production unit of whatever kind besides.

The world's largest FPSO is Egina congenital for the remote Nigerian same-name oil field. She is 330 m long while her storage capacity reaches 2.3 million barrels of oil. We described Egina'south dubious fate in the Offshore Giants: the Largest Oil and Gas Units article.

Incidentally, floating units used exclusively for storage of hydrocarbons are called FSO; and usually these are refurbished Supertankers.

Jack Upwards Rig

Jack Up drilling platform is rightly considered to be one the most user-friendly Mobile Offshore Drilling Unit of measurement (MODU) in the industry. The era of jack ups has started back in 1954 when Leon B. DeLong in cooperation with McDermott adult the first mobile unit for Apprehensive Oil. It was called DeLong-McDermott No.1 and had x legs with white potato cans.

Jack ups accept been refined into technological masterpieces since that time. Now they are easy to ship (usually past AHTS or Heavy-Lifts), merely there are also self-propelled rigs. They are more stable than semi-submersibles and cheaper than FPSO or drillships. However, its advantages impose certain limitations, i.e. jack up can drill up to the water depth of 107 m (350 ft) simply.

Jack Ups differ by the number of characteristics:

- Number of legs (there can be either 3 or four ones);

- Legs designs: open-truss legs which are made of crisscrossed tubular steel sections and columnar legs fabricated of immense steel tubes. The latter are cheaper to produce, but tin be used up to 76 m (250 ft) h2o depth because they prove to be less durable.

- Leg support: there can be a mat support that connects all legs and i ndependent-legged rigs with spud similar support.

- Drilling device design: the nearly popular are cantilevered jackups where drilling derrick is mounted on the arm placed out of the drilling deck. The other option is the slot-blazon jackup . These types have the drilling equipment in the special slot in the drilling deck.

Jack-Up Platform Jobs

Multi Office Support or Supply Vessels (MRSV)

MRSVs are incredibly pop among offshore shipowners. These are big vessels (normally about DWT 4500) equipped with diverse servicing equipment such as knuckle smash cranes, ROVs, diving units and so on.

MRSV are capable of offshore construction, ROV and diving back up, and so usually furnished with DP 2 or DP iii systems, thrusters and avant-garde navigational equipment besides equally helideck.

Probably the best example of the Multi Role Back up Vessel is DP3 Grand Canyon II which is equipped for all the abovementioned offshore jobs.

MRSV Jobs

Offshore Construction Vessel

Offshore Construction Vessels (OCV) are huge and technologically advanced vessels used for deep sea and subsea construction or vice versa decommissioning of offshore structures. For instance, OCV might be contracted to build a wind farm, oil platform, take part in a pipe laying project or dismantle a drilling rig.

Every bit a rule, these are DP vessels with heavy-duty cranes, pipe-laying, ROV and other essential offshore modules. The largest Offshore Construction Vessel today proves to be the Allseas' Pioneering Spirit congenital in 2016. She is a gigantic catamaran measuring 382 metres in length and 124 metres in width which is the size of 6 football pitches; while her cranes tin cover the distance of the eight football fields.

The gap betwixt ii hulls reaches 122 metres past 59 metres and accommodates another vessel, barge 'Iron Lady'. Moreover, Pioneering Spirit is able to work as a floatel as information technology hosts 560 crew members and offshore specialists. At nowadays, she works in the Danich sector of the Northward Bounding main in Tyra field recycling drilling rigs there on behalf of Total.

Structure Vessel Jobs

Piping Laying Vessel

Pipe-laying vessels are amongst the largest offshore ships. They are used for the installation of the marine pipeline infrastructure for instance from drilling provinces to onshore refineries and then on.

Pipelayers usually suit an extensive crew of higher up 100 crew members. At that place are unremarkably high requirements for the crew as the vessel works in DP mode constantly and is equipped with a heavy-duty crane and sophisticated mechanisms such equally 'S-laying' or 'J-laying' pipe laying equipment.

- The term 'S-laying' derives from the shape of the arc piping taken when information technology'due south let up from the vessel to be put in the water. The position of the mechanism aboard the vessel laying out the pipes is completely flat which allows the pipes to have the unique S-shaped curve.

- The 'J-laying' pipe laying mechanism is positioned perpendicularly; that enables it to control the curve of the pipe as it is lowered into the required depths of the water and provides the J-shaped curve.

- In that location is also the technology when the entire pipeline is installed using buoys and tugs; once the pipeline is built and the desired spot reached the buoys are removed and pipeline submerges.

Pipe Laying Vessel Jobs

Platform Supply Vessel (PSV)

Probably the near pop blazon of offshore vessels. Platform Supply Vessels (PSV) are used to deliver stores, necessary equipment and drilling consumables from shore bases to the drilling platform.

PSV are designed to have span structures in the front end and vast cargo areas on the deck. There are as well double-hull tanks for liquid cargo (drill mud, methanol, chemicals) and dry cargo that are transported in the special tank on the aft open up deck.

Typical PSV ranges from 50 to 100 one thousand in length; it usually spends virtually 25% of its operational fourth dimension loading, most of the time (most 40%) sailing to rig or platform at 14 -sixteen knots and the rest of the operational time is occupied past discharging ofttimes in drastic conditions. That is why Platform Supply Vessels are equipped with DP1 or DP2 systems.

PSV jobs are versatile and paid differently depending on the vessel and conditions. The number of crew members can reach 36 seamen.

Similar to other industries, offshore vessels switch to a green propulsion. The Viking Energy has become the offset LNG-fuelled PSV in the globe. She was built in Gdańsk (Poland) and later towed to Kleven Verft (Ulsteinvik, Kingdom of norway) for outfitting.

PSV Viking Free energy is not but large (the overall length of is most 95 m), but a very safe vessel. In that location is a special reservoir reminiscent of "thermos flask" in the middle of the vessel that guards the LNG fuel against insidious North seas.

PSV Vessel Jobs

ROV Support Vessels

Today ROV Back up Vessels are the highly sophisticated offshore ships equipped for diverse ROV operations. A remotely operated vehicle (ROV) is an unmanned underwater vehicle continued to the transport through wires and computer-controlled. ROVs are used for hydrographic researches, underwater inspections (hulls, pipelines, etc.), marine archeology and a lot more than.

Therefore, ROV Support vessels ordinarily are fitted with more than advanced DP systems, thrusters and reference systems to ensure redundancy and total control over ROV operations.

Incidentally, the first ROV, the motorcar called Poodle, was created back in 1953 past Dimitri Rebikoff, merely information technology wasn't until the U.s. Navy started to employ remotely operated vehicles for the recovery of the lost sunken torpedos that the ROV applied science had gained a wide acknowledgement.

Seismic Vessels or Survey Ships

Offshore vessels defended for geological research.These ships are equipped with special transmitters which fire audio waves into the bottom of the sea. The echo of the shot is captured and analyzed by the special buoys/ hydrophones towed behind the vessel.

The deck is unremarkably crammed with winches and storage reels. Another special feature of survey vessels is minimal propeller noize and precise station keeping to avoid interference with the survey equipment.

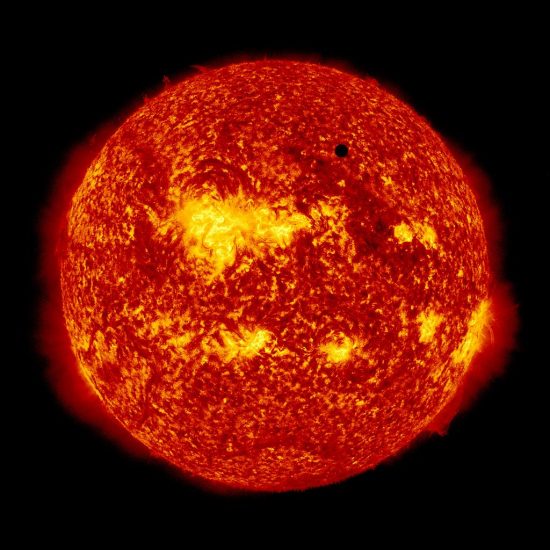

Seismic vessels are used in oil and gas exploration besides as a wide range of scientific research. Incidentally, the commencement research vessel is Capt. Cook's HM Bark Endeavour which departed from Plymouth in August 1768 for its terra incognita expedition to Commonwealth of australia and New Zealand. The goal of the trek was to reach Tahiti in time to observe the transit of Venus across the Sun in 1769.

This was an incredibly important observation as capturing transit of Venus across the Sun from dissimilar spots of the planet used to be the only way of measuring the altitude between the Sun and Earth at that time.

By the way, this item Cook's expedition has been a game changer for all seafarers because Cook has decided to use the fourth dimension of the sail to prove that citrus fruit and vegetables are able to preclude scurvy. Naturally, he was successful, so fruits and vegetables have been included into the diet of seafarers on all vessels since that time. Past the way, information technology had been normal to lose half of the coiffure to scurvy in long sailings before HM Bark Endeavour's voyage.

Seismic vessels have developed significantly since that memorable trek. Today the most dedicated ones don't even look like a conventional vessel. Come across Ramforms from PGS Company. They are specially designed for marine inquiry with GeoStreamer engineering science that improves data from sensors and special dorsum deck construction.

Shuttle Tanker

Shuttle Tanker is a specialized tanker used for oil transportation from the oilfield to the refinery. The technology was first used in 1970s in the North Sea equally an alternative to pipeline, simply the development of the Dynamic Positioning and further retreating of oil exploration to the bounding main fabricated Shuttle Tankers the existent game changers in 2011 when Petrobras introduced them into their Cascade and Chinook fields operations.

Shuttle Tanker Jobs

Wind Subcontract Installation Vessels (WIV)

WIV are robust offshore vessels constructed for transportation and installation of wind turbines. Equally the bulk of offshore vessels, they evidence to be very complex structures. For example, they have to be big enough to carry offshore foundations, manoeuvrable to squeeze through offshore current of air farms and possess constructional capabilities to install current of air foundations in whatever weather.

The world's largest wind farm installation vessel is about to be delivered to Jan De Nul Grouping. The Voltaire will be 181.78 yard long (incl. helideck) and accept sixty m in beam. It's deadweight will accomplish 21,500 t and the Huisman crane has a max lifting capacity of 3000 t.

The vessel is assigned for the construction of the 3.6GW Dogger Bank Wind Farm. The projection is situated 130 km off the Yorkshire coast and is a joint venture between SSE Renewables and Equinor. Once completed in 2023 Dogger Bank volition be able to supply v% of the UK electricity needs.

Author: Filip Drozda

Author: Filip Drozda

Filip is a maritime professional. He has been working in the aircraft industry for 25 years. Mr. Drozda is an expert in crewing for dry cargo and offshore vessels; has a strong technical groundwork, speaks Polish, English and Russian languages.

Source: https://maritime-zone.com/en/news/view/types-of-offshore-vessels

Posted by: cephaswhersely1982.blogspot.com

0 Response to "How Many Vessels Are Registered In Manteca, Ca"

Post a Comment